Expert tips for a longer printhead life

Companies in all industries use thermal transfer and direct thermal printers to print barcodes and labels. The printer head is one of the most important and costly components. It’s in the frontline of wear, they are delicate and can be quite costly. The tips from experts in this article will help you get the longest life from your printhead. You will save money by replacing them less often.

With this article, we provide answers to the most common questions about the life and performance of a printhead. You’ll get tips to get the best print results and longest life from your printheads.

Between our 30 years of experience supplying printer equipment, and the recommendations from labelprinter manufacturers like Zebra®, Sato®, Honeywell®, Videojet® and TSC/Printronix®, you can rely on the best expert tips for a longer printhead life.

How long does a thermal printhead typically last?

There is no single answer to this question. It depends on the intensity of use, your print quality requirements, and variables like printer settings and the use of ink ribbons. According to the manufacturer specifications, a printhead might print up to 10 million labels. But in reality this could be more. Or less, depending on your actions and settings.

The good news is that you can have a positive effect on the lifetime of the printheads yourself. And it’s not difficult to start making a real impact today.

Expert tip 1: A printhead can last 3 times longer by using a ribbon

According to printer manufacturer Videojet®, “it is not unusual for a printhead to last up to a year in an average throughput application”. This is based on a printhead life of 200 km, with a 130mm long message, printing 5000 labels a day, 6 days a week.

In the same white paper they state that a printhead that operates in Direct Thermal (DT) mode might only last 1/3 as long as one that operates in Thermal Transfer (TT) mode.

With direct thermal labels (which don’t require a ribbon), the more abrasive or rough paper label is in direct touch with the printhead surface. This takes a big toll on the printhead. In addition, direct thermal printing requires a higher printhead temperature which again will shorten its life.

If you use standard paper labels (which do require a ribbon), the ink ribbon provides an extra layer of protection to the printhead. The ribbon is a much smoother surface, which leads to less wear.

In addition, wax ribbons require a lower temperature setting than printing direct on paper.

Finally, when using thermal transfer, it’s important to make sure that both the ribbon and labels are of good quality and matched appropriately. Make sure that the ribbon is slightly wider than the label. This way, the label is not exposed to the print head itself.

Expert tip 2: Save money by cleaning your printhead

The lack of regular cleaning and preventive maintenance is the leading factor in premature printhead failures. This means you need to replace more printhead over the lifetime of a printer. Printhead cleaning will save you money.

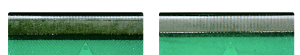

The result of cleaning the printhead regularly is clear!

Paper causes dust that might lead to scratches. Ink leaves a residue. Labelprinter manufacturers recommend that you clean the print head and platen roller after every ribbon or label roll change with a certified printhead cleaning product.

A brand like 4U offers different types of cleaning products based on isopropyl alcohol. The most common examples are cleaning wipes, pens, and swabs.

But how do you know which type of cleaning product to use? It depends mostly on your preference and experience. In general, cleaning wipes are the most versatile choice, as they will remove the residue from both the printhead and platenroller. Doing this regularly is the easiest way to get the most mileage out of the print head. Anyone can do it.

Expert tip 3: Change your printer settings for a longer printhead life

Your printer settings have a large impact on the life of a printhead. Higher temperature, darkness settings and printhead pressure will all shorten the life of the printhead.

- Higher printhead temperatures give you better resolution. But setting the temperature too high will shorten printhead life. Test the print quality and set the lowest temperature for an acceptable print quality. Beware of a spiral effect. If you don’t clean the printhead often enough, you’ll probably need to increase the printhead heat to get the same quality. The increased temperature leads to more residue and might ultimately damage the printhead.

- Printing at a higher speed requires a higher temperature setting. Just because your printer can reach a speed of 12 inch per second (ips), it doesn’t mean you have to. If a lower speed is acceptable in your print application, you will get more mileage out of your printhead.

- If your printer offers adjustable pressure settings, choose a lower pressure if it still produces good quality images. Lower pressure means less friction. That means a longer life from the printhead.

Bonus tips for a longer printhead life

Some of the tips may seem obvious, but they can still have a big impact on the printhead life.

- Don’t touch the printhead element surface with your hands

- Only use cleaning products that were designed for cleaning printheads

- Use high-quality labels and ribbons

- Use the right size ribbon. Too narrow may cause additional wear to the printhead

- Choose a printer grade (eg industrial) to fit your (harsh) environment

- When replacing printheads, follow the printer manual instructions

- Don’t use any sharp object to remove dirt or residue that is sticking to the head

When is it time to replace the printhead?

You’ll know that the end of a printhead life is near when you start to see white lines, light images and unreadable or non-compliant barcodes.

If you experience any of these symptoms, visually inspect and clean the printhead. Test if that solves the issue. If not, it might be time to replace it.

If you see a white line across your labels, it’s probably a void in your printhead. One or more dots on the head are damaged. That means it’s time for a new printer head.

Check the pricing and availability of your thermal printhead in our webshop